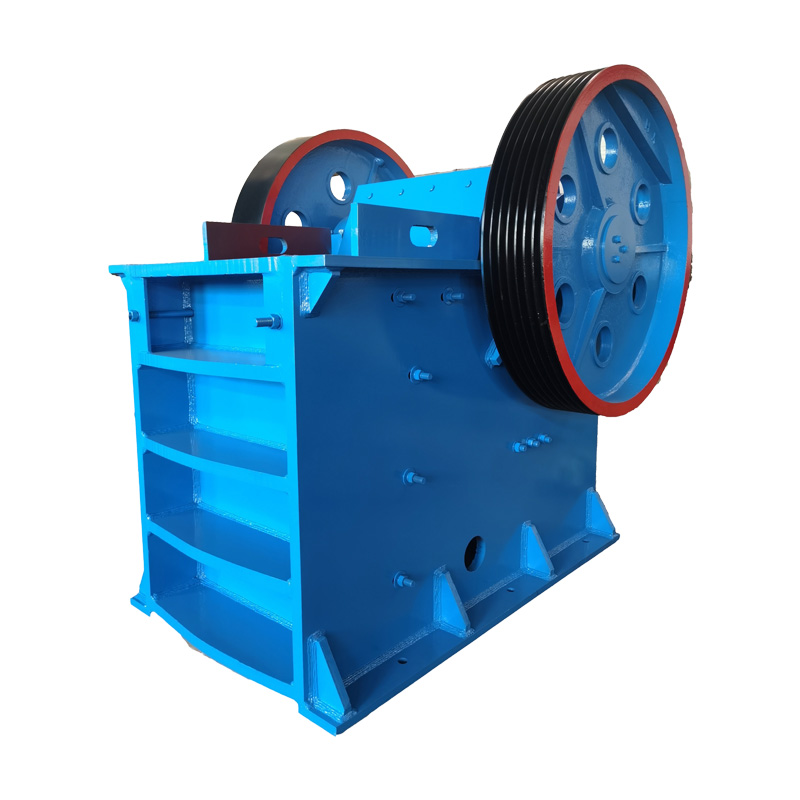

Robust structure

There are two types of machine frame: welded model and assembled model. The former is for small and middle size, and the latter is for big size.

The welded type adopts large arc fillet and low stress welding method, greatly reduces the concentration stress which ensures rack equal strength in all directions, high impact resistance, even force, low failure rate.

Assembled uses advanced modularization and non-welded frame structure design of high fatigue strength and high reliability. Meanwhile machine assembly design makes transportation, and installation more convenient, especially suitable for installation in narrow and small places like undermine and high altitude mining.

Optimized cavity structure

Symmetrical V formed design, toggle of large obliquity, long stroke, reasonable rotor speed, allow larger materiel block in feeding, higher productivity, homogeneous output granule, less attrition for jaw plate.

The whole set of heavy movable jaw plate is durable

The whole set of heavy movable jaw plate integrates forged heavy eccentric shaft, high quality bearing of heavy loading, the design of movable jaw plate optimized by finite element analysis. These features assure the stroke resistance and stability. Labyrinth seal and centralized lubricating system prevent the greese of bearing not to be contaminated, and assure the easy lubrication which results in longer function and more stability.

Protective planch of movable jaw plate

Heavy protective planch installed above the movable jaw plate protects internal bearing from damage caused by material falling down in feeding moment.

One piece cast of bearing seat

One piece cast of bearing seat assures good match with frame, and avoids unnecessary radio direction pression for bearing in fastening process which occurs usually to composed bearing seat. Therefore, bearing can function more stably.

Installation integrating motor & crusher

Integrative installation of motor chassis and crusher frame not only saves installation space of jaw crusher but also reduces the length of Vee belt. Thanks to synchronous movement of crusher frame, motor chassis and motor. Adjustable motor chassis can realize the adjustment of Vee-belt’s tensile force to make the Vee-belt more durable.

Shock absorber installation

The crusher is fixed by the device of special rubber shock absorber, which absorbs effectively the its vibration at the peak point and meanwhile, allows crusher to displace in vertical and horizontal direction. In this way, the shock to foundation would be reduced.

The motor drives belt and pulley. The movable jaw swings up and down before and after through the eccentric shaft. When the movable pushes the movable jaw plate to the fixed jaw plate, the material is crushed or split into pieces. When the movable jaw and movable jaw plate springs back in the effect of eccentric shaft, the material previously have been crushed discharges from the discharge opening of the lower part. With the motor continuously rotating, the movable jaw breaks and discharges material periodically to achieve mass production.

| Model | Feeding port size (mm) | Max feeing Size(mm) | Discharging size(mm) | Capacity (t/h) | Power (kw) | Weight (t) | Size (mm) |

| PE250×400 | 400×250 | 200 | 20-50 | 5-20 | 15 | 3 | 1430×1310×1340 |

| PE400×600 | 400×600 | 350 | 40-100 | 15-60 | 30-37 | 7 | 1700×1732×1653 |

| PE500×750 | 500×750 | 425 | 50-100 | 40-110 | 45-55 | 12 | 2035×1921×2000 |

| PE600×900 | 600×900 | 480 | 65-160 | 90-180 | 55-75 | 17 | 2290×2206×2370 |

| PE750×1060 | 750×1060 | 630 | 80-140 | 110-320 | 90-110 | 29 | 2655×2302×3110 |

| PE900×1200 | 900×1200 | 750 | 95-165 | 220-450 | 110-132 | 58 | 3800×3166×3045 |

| PE1000×1200 | 1000×1200 | 850 | 200-300 | 280-560 | 110-160 | 69 | 5350×4280×3050 |

| PE1200×1500 | 1200×1500 | 1020 | 150-300 | 400-800 | 160-220 | 100.9 | 6380×5310×3710 |

| PE1500×1800 | 1500×1800 | 1200 | 210-360 | 520-1100 | 280 | 132 | 7460×6235×4249 |

| PEX150×250 | 150×250 | 125 | 10-40 | 1-3 | 5.5 | 1.5 | 896×745×935 |

| PEX150×750 | 150×750 | 125 | 18-48 | 5-16 | 15 | 3.8 | 1200×1500×1200 |

| PEX250×750 | 250×750 | 210 | 25-60 | 15-30 | 22-30 | 5 | 1667×1545×1020 |

| PEX250×1000 | 250×1000 | 210 | 25-60 | 15-50 | 30-37 | 7 | 1550×1964×1380 |

| PEX250×1200 | 250×1200 | 210 | 25-60 | 20-60 | 37-45 | 8.5 | 2192×1900×1950 |

| PEX300×1300 | 300×1300 | 250 | 20-90 | 30-90 | 55-75 | 11.5 | 1750×2320×1724 |