Product Introduction

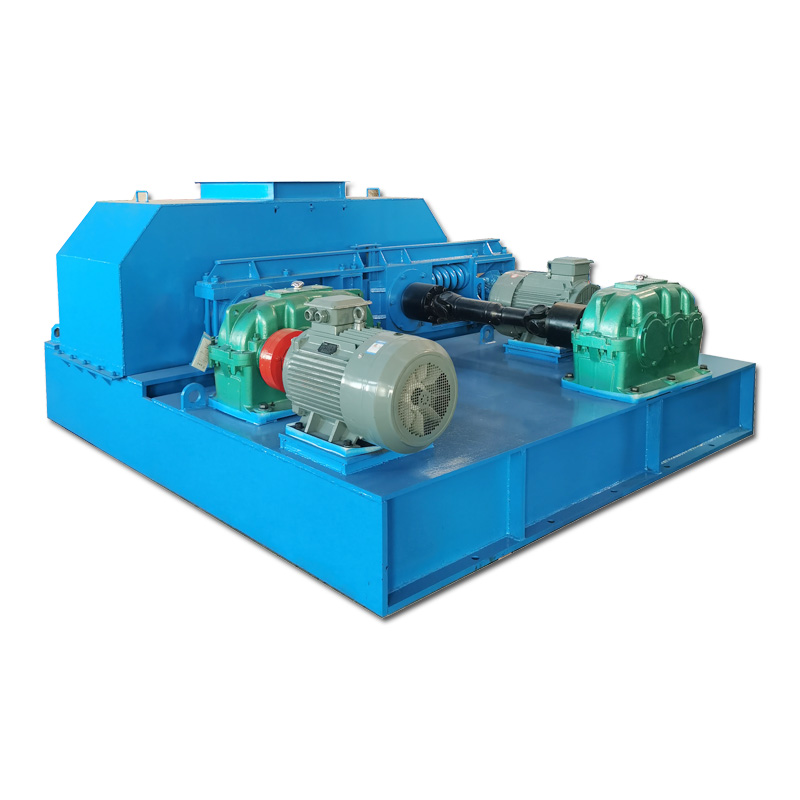

Double roll crusher is specially used to break small materials equipment, it can also be called roll sand making machine, roll crusher and so on. Mainly for all kinds of materials of fine crushing sand operation. Hundreds of raw materials below 6cm can be processed into 5mm below, the yield can reach 95% or more, the discharge particle size can be adjusted arbitrarily, and the service life of wearing parts is 1-3 years. Moreover, the double roll crusher has small size, small footprint and easy maintenance. In the sand making equipment, the roller crusher price is low, the purchase cost is low, and the grain type is also better. The noise of roll crusher is lower than 70 decibels, the noise pollution is small, and the effect of environmental protection is played.

Scope of application

The machine is suitable for building materials, cement, chemical, refractory, coal, mineral processing, sinter, silicate, glass, abrasives, ceramics and other industrial sectors, can handle a variety of medium and high hardness (160Mpa below) ore and rock crushing and fine crushing. Roller crusher can handle materials are: steel slag, river pebbles, pebbles, calcite, quartz, glass, marble, bentonite, bluestone, steel slag, limestone, weathered sand, granite, basalt and so on. Especially in the sand making industry and building materials industry, it has a good effect on small materials, and has great advantages compared with other crusher equipment.

Working principle

The roller crusher mainly uses two sets of independently driven rollers to break materials through the extrusion and grinding force generated by relative rotation. The material falls between the two rollers through the feed port, and the finished product falls naturally after being crushed by the pair of rollers. When encountering hard or unbreakable materials, the roller can automatically retreat under the action of the hydraulic cylinder or spring, so that the gap between the two rollers increases, and the hard or unbreakable materials naturally fall to ensure that the machine is not damaged. By adjusting the pressure of the hydraulic cylinder or spring, the pressure between the two rollers increases or decreases to control the size of the finished product, and the greater the pressure, the smaller the finished product.

Performance characteristics

1. Equipped with roll crusher on the sand production line, the production capacity of the sand making equipment can be fully utilized, which can generally increase the output by 30%-40%, and the total energy consumption can be reduced by 20%-30%. For sand making systems with production capacity requirements, the installation of a rolling machine can significantly save investment.

2. Simple structure, small space, easy operation and maintenance, less dust, low noise, environmental protection and pollution-free.

3. Long service life, low operating cost, wear parts roller skin with new wear-resistant materials, can greatly improve the service life, reduce later replacement costs.

4. The roller crusher is equipped with safety protection device. When metal filings enter the crushing chamber, the roller bullets open, the iron filings leak out, and the equipment runs normally.

5. The roll gap of the roll crusher can be arbitrarily adjusted between 1-20mm, and after adjusting the roll gap according to the requirements of the crushing size, the finished particles can be effectively controlled, and all materials are discharged from the bottom of the crushing chamber with the ideal particle size.

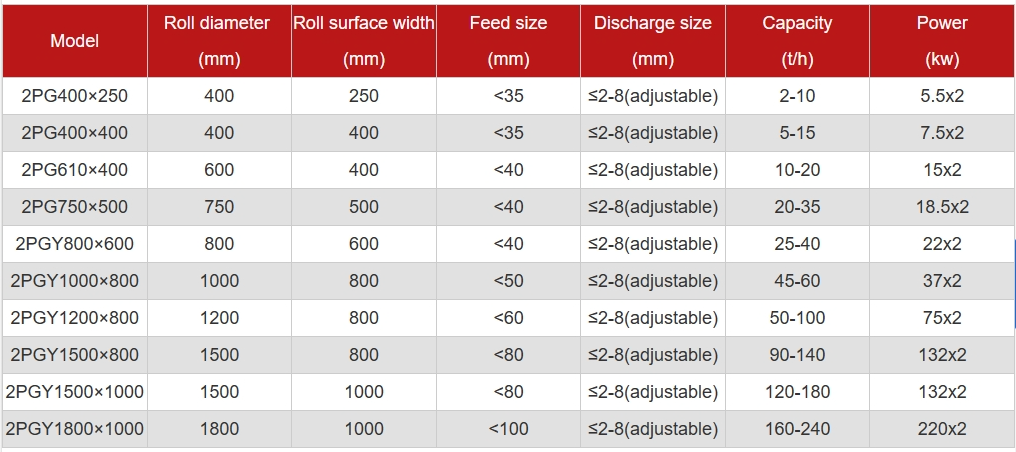

Model parameter

Note: The equipment is constantly updated and improved, if the model parameters change, please refer to the contact.