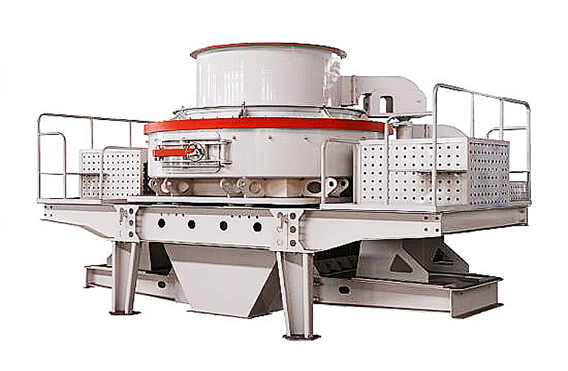

FEATURES AND TECHNOLOGY ADVANTAGES OF VSI SERIES VERTICAL SHAFT IMPACT CRUSHER

Simple and reasonable structure, low cost.

High crushing ratio, energy saving.

Fine crush and grind.

Moisture content of raw material up to about 8%.

Suitable for crushing hard material.

Excellent shape of final product.

Small abrasion, easy maintenance.

Noise when working is below 75dB.

APPLICATION OF VSI SERIES VERTICAL SHAFT IMPACT CRUSHERS

River stone, mountain stone(limestone, basalt, granite, diabase, andesite.etc), Ore tailings, aggregate chips.

Hydraulic and hydroelectric engineering, high-level road, highway and railway, passenger rail line, bridge, airport runway, municipal projects, sand making and rock reshaping.

Building aggregate, highway road fabrics, cushion material, asphalt concrete and cement concrete aggregate.

Crushing progress before grinding in mining field. The crushing of building material, metallurgy, chemical industry, mining, fireproofing, cement, abrasive, etc.

Breaking of high abrasive and secondary disintegration, sulfur in thermal power and metallurgy industry, environmental projects such as slag, construction waste crushing.

Manufacturing of glass, quartz sand and other high purity material.

WORKING PRINCIPLE OF VSI SERIES VERTICAL SHAFT IMPACT CRUSHER

The materials fall into impeller with high-speed rotation vertically. On the force of high-speed centrifugal, the materials strike to the other part of material in a high speed. After mutual impacting, the materials will strike and rub between the impeller and the casing and then be discharged straight from the lower portion to form a closed multiple cycles. Final product is controlled by screening equipment to meet the requirement.

The VSI series vertical impact crushers has two types: rock-on-rock and rock-on-iron. Rock-on rock is to process abrasive material and rock-on –iron is to process normal material. The production of rock-on-iron is 10-20% higher than rock-on-rock.

Technical Data of VSI Series Vertical Shaft Impact Crusher:

| Model | VSI-7611 | VSI-8518 | VSI-9526 | VSI-1140 | VSI-1145 | ||

| Capacity (t/h) | Center and Ring feeding | 120-180 | 200-260 | 300-380 | 450-520 | 490-600 | |

| Center feeding | 60-90 | 100-130 | 150-190 | 225-260 | 250-310 | ||

| Max Feed Size (mm) | Soft material | <35 | <40 | <45 | <50 | <50 | |

| Hard material | <30 | <35 | <40 | <45 | <45 | ||

| Rotation speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | 1180-1280 | ||

| Power for double motor (kW) | 110-150 | 180-220 | 264-320 | 400-440 | 440-520 | ||

| Overall Dimension L×W×H (mm) | 3700×2150×2100 | 4140×2280×2425 | 4560×2447×2778 | 5000×2700×3300 | 5100×2790×3320 | ||

| Weight (t) | 7.5 | 10.5 | 14 | 16 | 27.5 | ||

| Power Source | 380v 50Hz | ||||||

| Vibrating Sensor | Inspect scope: 0.1-20mm/s adjusted continuously | ||||||

| Lubrication hydraulic pressure station | Power for double oil pump | 2×0.31kW | |||||

| Safety | To make sure the supply of the oil with double oil pump; stop working without oil or hydraulic pressure; temperature falls when the water cools; start the motor by heating it in winter. | ||||||

| Power for oil box heater | 2 kW | ||||||