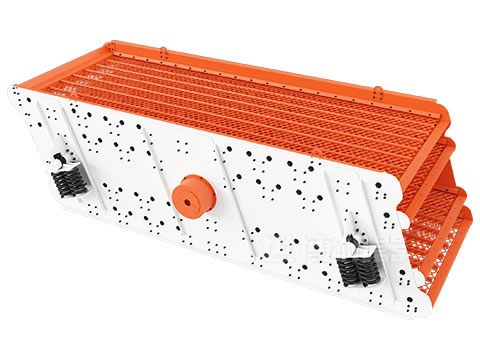

Product Introduction

The circular vibrating screen machine mainly consists of a screen box, screen mesh, vibrator, vibration damping spring device, base frame, etc. Using a cylindrical eccentric shaft vibrator and eccentric blocks to adjust the amplitude, the vibrator is installed on the side plate of the screen box and is driven by an electric motor through a V-belt to rotate, generating centrifugal inertia force and forcing the screen box to vibrate. The side plate of the screening machine is made of high-quality steel plate, and the side plate is connected to the crossbeam and exciter base with high-strength bolts or ring groove rivets. The vibrator is installed on the side plate of the screen box and is driven by an electric motor through a coupling to rotate, generating centrifugal inertia force and forcing the screen to vibrate.

Advantages and characteristics

1. It mainly consists of a sieve box, an exciter, a suspension (or support) device, and an electric motor. The electric motor drives the main shaft of the shaker to rotate through a V-belt. Due to the centrifugal inertia force of the unbalanced weight on the shaker, the screen box vibrates. By changing the eccentric weight of the exciter, different amplitudes can be obtained.

2. Due to the strong vibration of the sieve box, the phenomenon of material blockage in the sieve holes is reduced, making the sieve have high screening efficiency and productivity.

3. The structure is simple and easy to disassemble and replace the screen surface.

4. Screening consumes less electricity per ton of material.

operational principle

The electric motor drives the eccentric block of the exciter to rotate at high speed through a triangular belt, which excites the screen box to produce a certain amplitude of circular motion. The material on the screen is subjected to the impulse transmitted by the screen box on the inclined screen surface, resulting in continuous throwing motion. During the process of the material meeting the screen surface, particles smaller than the sieve hole are allowed to pass through the screen, thus achieving classification.

technical parameter

Model | Screen size W×L(mm) | Number of layers | mesh size(mm) | Feed size(mm) | Capacity(t/h) | Power(kw) | Vibration frequency(r/min) | Double amplitude(mm) |

2YZK1237 | 3700×1200 | 2 | ≤400 | 3-50 | 30-100 | 5.5 | 970 | 5-9 |

3YZK1237 | 3700×1200 | 3 | ≤400 | 3-50 | 30-100 | 7.5 | 970 | 5-9 |

2YZK1548 | 4800×1500 | 2 | ≤400 | 3-100 | 30-275 | 15 | 970 | 5-9 |

3YZK1548 | 4800×1500 | 3 | ≤400 | 3-100 | 30-275 | 15 | 970 | 5-9 |

2YZK1848 | 4800×1800 | 2 | ≤400 | 3-100 | 56-330 | 18.5 | 970 | 5-9 |

3YZK1848 | 4800×1800 | 3 | ≤400 | 3-100 | 56-330 | 18.5 | 970 | 5-9 |

4YZK1848 | 4800×1800 | 4 | ≤400 | 3-80 | 56-330 | 22 | 970 | 5-9 |

2YZK1860 | 6000×1800 | 2 | ≤400 | 3-100 | 65-586 | 18.5 | 970 | 5-9 |

3YZK1860 | 6000×1800 | 3 | ≤400 | 3-100 | 65-586 | 22 | 970 | 5-9 |

4YZK1860 | 6000×1800 | 4 | ≤400 | 3-100 | 65-586 | 30 | 980 | 5-9 |

2YZK2160 | 6000×2100 | 2 | ≤400 | 3-100 | 81-720 | 22 | 980 | 5-9 |

3YZK2160 | 6000×2100 | 3 | ≤400 | 3-100 | 81-720 | 30 | 970 | 5-9 |

4YZK2160 | 6000×2100 | 4 | ≤400 | 3-100 | 81-720 | 30 | 980 | 5-9 |

2YZK2460 | 6000×2400 | 2 | ≤400 | 3-150 | 100-810 | 22 | 970 | 5-9 |

3YZK2460 | 6000×2400 | 3 | ≤400 | 3-150 | 100-810 | 30 | 980 | 5-9 |

4YZK2460 | 6000×2400 | 4 | ≤400 | 3-150 | 150-850 | 37 | 980 | 5-9 |

2YZK2870 | 7000X2800 | 2 | ≤400 | 5-100 | 120-680 | 22x2 | 750 | 8 |

3YZK2870 | 7000X2800 | 3 | ≤400 | 5-100 | 180-720 | 22x2 | 750 | 8 |

2YZK3070 | 7000X3000 | 2 | ≤400 | 5-100 | 200-700 | 37 | 750 | 8 |

3YZK3070 | 7000X3000 | 3 | ≤400 | 5-100 | 230-800 | 45 | 750 | 8 |